Summary:

A new method for producing porous graphene membranes could transform the future of carbon capture by making it more affordable and scalable. Researchers at EPFL have developed a technique to manufacture large-area graphene membranes that selectively filter carbon dioxide (CO2) from gas mixtures, offering a promising alternative to current carbon capture technologies that are costly and energy-intensive.

The study is published in Nature Chemical Engineering.

Graphene, just one atom thick, has long intrigued scientists for its potential in gas separation, but efforts to scale up production for real-world use have faced significant hurdles. The EPFL team, led by Professor Kumar Agrawal, addressed key barriers by growing high-quality graphene on low-cost copper foils and using a refined ozone etching method to create nanoscale pores ideal for CO2 filtration. They also introduced a new membrane transfer technique that avoids cracks and preserves membrane integrity.

The result is a 50 cm2 graphene membrane with exceptional CO2 selectivity and high gas permeance — both crucial for effective carbon capture. Unlike conventional methods that depend on chemical solvents and heat, these membranes function through simple pressure-driven filtration, drastically lowering energy demands. The innovation holds potential not only for carbon capture but also for applications like hydrogen purification and oxygen production.

Scalable graphene membranes: a leap for carbon capture

Capturing carbon dioxide (CO2) from industrial emissions is crucial in the fight against climate change. But current methods, like chemical absorption, are expensive and energy-intensive. Scientists have long eyed graphene — an atom-thin, ultra-strong material — as a promising alternative for gas separation, but making large-area, efficient graphene membranes has been a challenge.

Now, a team at EPFL, led by Professor Kumar Agrawal, head of the Gaznat Chair in Advanced Separations, has developed a scalable technique to create porous graphene membranes that selectively filter CO2 from gas mixtures. Their approach slashes production costs while improving membrane quality and performance, paving the way for real-world applications in carbon capture and beyond.

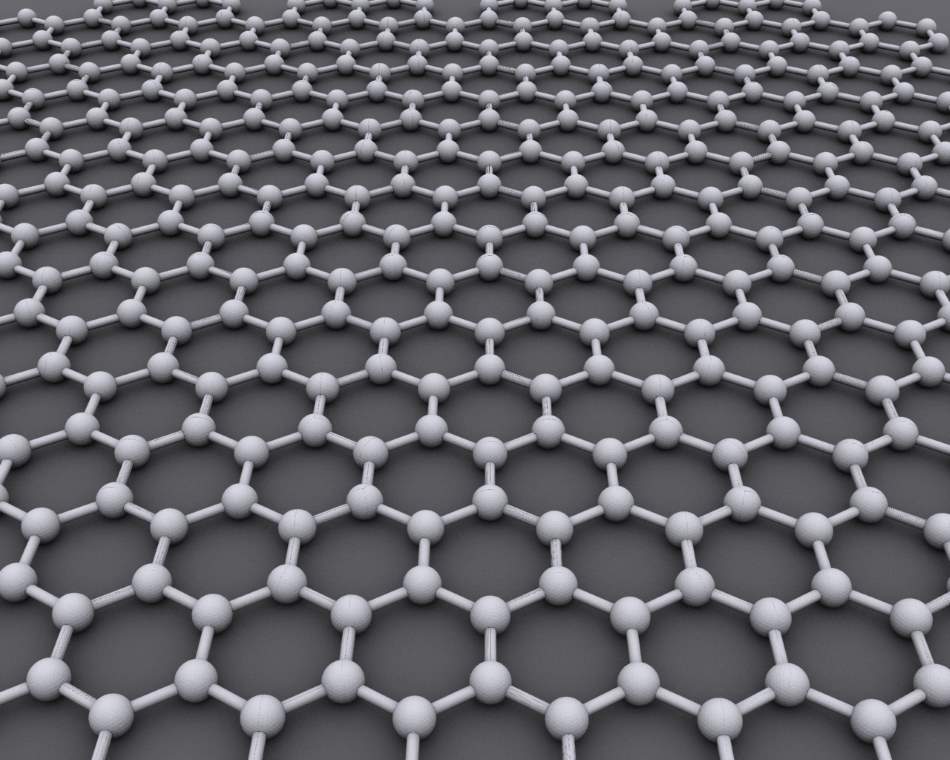

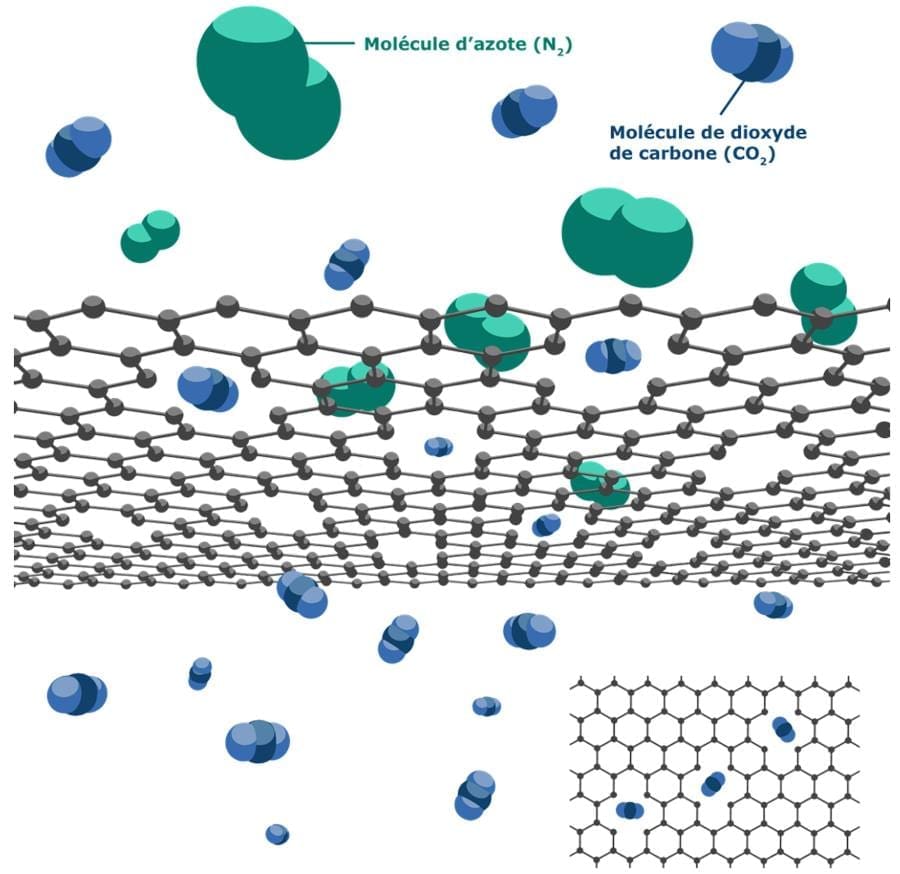

Graphene membranes are excellent at separating gases because they can be engineered with pores just the right size to let CO2 through while blocking larger molecules like nitrogen. This makes them ideal for capturing CO2 emissions from power plants and industrial processes. But there’s a catch: manufacturing these membranes at a meaningful scale has been difficult and costly.

Most existing methods rely on expensive copper foils to grow high-quality graphene needed for membranes and require delicate handling techniques that often introduce cracks, reducing membrane efficiency. The challenge has been to find a way to create large, high-quality graphene membranes in a cost-effective, reproducible manner.

The EPFL team tackled these challenges head-on. First, they developed a method to grow high-quality graphene on low-cost copper foils, dramatically cutting down material expenses. Then, they refined a chemical process using ozone (O₃) to etch tiny pores into the graphene, allowing for highly selective CO2 filtration. Crucially, they improved how the gas interacts with the graphene, ensuring uniform pore formation over large areas — a key step toward industrial scalability.

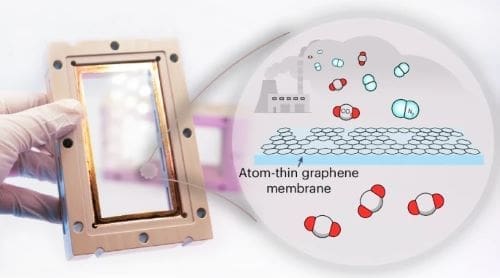

To solve the issue of membrane fragility, the researchers also introduced a novel transfer technique. Instead of floating the delicate graphene film onto a support, which often leads to cracks, they designed a direct transfer process inside membrane module that eliminates handling issues and reduces failure rates to near zero.

Using their new approach, the researchers successfully created 50 cm2 graphene membranes — far larger than what was previously feasible — with near-perfect integrity. The membranes demonstrated exceptional CO2 selectivity and high gas permeance, meaning they efficiently let CO2 through while blocking unwanted gases.

Moreover, by optimizing the oxidation process, they were able to increase the density of CO2-selective pores, further enhancing performance. Computational simulations confirmed that improving gas flow across the membrane played a crucial role in achieving these results.

This breakthrough could change the game for carbon capture. Traditional CO2 capture technologies rely on energy-intensive chemical processes, making them complex and expensive for widespread use. Graphene membranes, on the other hand, require no heat input, and operate using simple pressure-driven filtration, significantly reducing energy consumption.

Beyond carbon capture, this method could be applied to other gas separation needs, including hydrogen purification and oxygen production. With its scalable production process and cost-effective materials, EPFL’s innovation brings graphene membranes one step closer to commercial viability.

***

Funding: GAZNAT, Swiss Federal Office of Energy, Bridge (Proof of Concept), Canton of Valais, Switzerland.

Journal Reference:

Jian Hao, Piotr Mieczyslaw Gebolis, Piotr Marcin Gach, Mojtaba Chevalier, Luc Sébastien Bondaz, Ceren Kocaman, Kuang-Jung Hsu, Kapil Bhorkar, Deep J. Babu, Kumar Varoon Agrawal, ‘Scalable synthesis of CO2-selective porous single-layer graphene membranes’, Nature Chemical Engineering (2025). DOI: 10.1038/s44286-025-00203-z

Article Source:

Press Release/Material by Nik Papageorgiou | EPFL

Featured image credit: AlexanderAlUS | CC BY-SA 3.0