Researchers at the Woods Hole Oceanographic Institution (WHOI) have made a significant breakthrough in the fight against plastic pollution in oceans.

After years of experimentation, a new version of cellulose diacetate (CDA), a wood pulp-derived polymer, has been found to be the fastest-degrading bioplastic tested in seawater. The CDA foam has the potential to replace long-lasting materials like Styrofoam, a common source of plastic pollution.

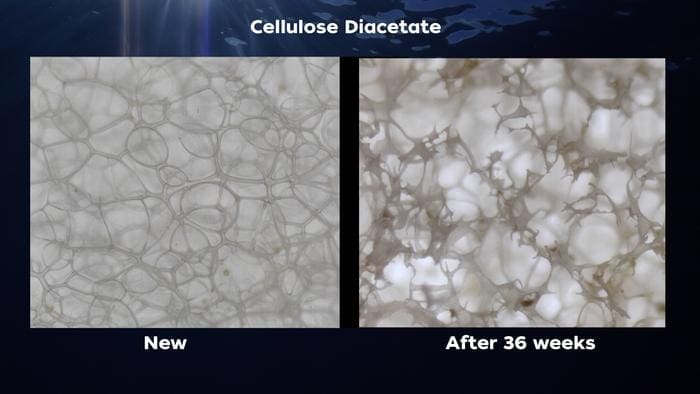

This discovery, outlined in a recent paper published in ACS Sustainable Chemistry & Engineering, showcases the ability of this new CDA foam to degrade 15 times faster than its solid form, even outpacing paper. The material is seen as a promising alternative to non-biodegradable plastics frequently found in single-use products such as straws, food packaging, and takeout containers.

“What excites me most about this study is its translational nature,” said Collin Ward, senior author of the study. “This study is the culmination of years of research focusing on understanding the fundamental controls on CDA biodegradation in the ocean.”

The WHOI team, including scientists Bryan James, Chris Reddy, Yanchen Sun, and Kali Pate, conducted the study in collaboration with Eastman, a bioplastic manufacturing company. The goal was to design a scalable, environmentally-friendly alternative to traditional plastic foams without requiring significant changes to existing production processes.

The experiment involved testing both foamed and solid CDA materials in a specially-designed flow-through seawater tank that mimicked oceanic conditions. By continuously replenishing seawater from Martha’s Vineyard Sound and maintaining a dynamic marine environment, the researchers could better simulate real-world conditions.

After 36 weeks, they found that foamed CDA lost 65-70% of its original mass, demonstrating a much quicker degradation than other tested materials.

“Using continuous flowing seawater tanks enables us to bring the dynamics of the microbially active ocean into the lab,” lead author Bryan James explained. “The ocean is continually changing, and it was important that we replicated this environment by replenishing microbes and nutrients, making for a much more environmentally realistic experiment.”

This research builds upon a previous study in which the team tested various straw materials, including solid and foamed CDA, plastic, and paper. In that study, CDA straws, particularly those made from foamed CDA, degraded at rates up to 190% faster than their solid counterparts, further demonstrating the potential of this material to replace more persistent forms of plastic.

One of the main advantages of CDA foam lies in its efficiency. “As a materials scientist and engineer, it’s been exciting to demonstrate that foams can be materially efficient, meaning they achieve functionality using the least amount of material possible, reducing cost and many environmental impacts,”,” said James. This reduces both the cost and environmental impact, making biodegradable foams a viable and sustainable replacement for traditional plastic foams.

The potential uses for this new material are vast, especially for replacing problematic plastics like Styrofoam, commonly used in food packaging and other single-use items. Eastman, the industrial partner in the research, has already introduced a compostable lightweight tray made from foamed CDA, which is intended to replace plastic trays in industrial food packaging.

Jeff Carbeck, Vice President of Corporate Innovation at Eastman, emphasized the importance of collaboration between academia and industry to tackle global challenges: “Partnerships between industry and academia are essential for accelerating solutions to the most urgent global challenges, where academia can provide unique insights, and industry partners can use those insights to develop solutions at scale. That is how our collaboration with WHOI works; they significantly broadened our understanding of how our commercial and developmental materials degrade.”

Carbeck also pointed out that embracing biodegradable materials in consumer goods is a crucial step in reducing the environmental impact of single-use plastics. “This research shows that biodegradable foams can offer the same functionality as traditional plastics while degrading quickly if they find their way into the ocean. It’s a critical step toward sustainability and preserving our oceans for future generations.”

According to Ward, the scalability of CDA foam is one of its biggest advantages. Companies currently producing Styrofoam-based products won’t need to invest in new equipment, making the switch to biodegradable alternatives seamless. “Advancing new plastics not made from fossil fuels, are compostable, and don’t persist in the environment as pollution, can be a win for consumers and the environment,” Ward explained.

This breakthrough signals hope in the ongoing efforts to curb plastic pollution. With biodegradable CDA foam proving to be both functional and environmentally-friendly, it could pave the way for a significant reduction in the plastic waste that ends up in the world’s oceans.

Journal Reference:

Bryan D. James, Yanchen Sun, Kali Pate, Rahul Shankar, Mounir Izallalen, Sharmistha Mazumder, Steven T. Perri, Katelyn R. Houston, Brian Edwards, Jos de Wit, Christopher M. Reddy, and Collin P. Ward, ‘Foaming Enables Material-Efficient Bioplastic Products with Minimal Persistence’, ACS Sustainable Chemistry & Engineering (2024). DOI: 10.1021/acssuschemeng.4c05822

Article Source:

Press Release/Material by Wood Hole Oceanographic Institution (WHOI)

Featured image credit: Rachel Mann | Woods Hole Oceanographic Institution