Scientists at Washington State University (WSU) have developed a new method to convert plant waste into sustainable aviation fuel (SAF), marking a significant step forward in reducing the aviation industry’s reliance on fossil fuels.

The process, recently published in Fuel Processing Technology, successfully transforms lignin – a tough, woody substance found in plant cell walls – into a viable jet fuel alternative.

“Our achievement takes this technology one step closer to real-world use by providing data that lets us better gauge its feasibility for commercial aviation,” said Bin Yang, lead researcher and professor at WSU’s Department of Biological Systems Engineering.

Lignin: a new frontier for jet fuel

Lignin, a byproduct of many agricultural processes, is abundant yet underutilized due to its complex chemical structure. Found in materials like corn stover (the leftover stalks, leaves, and cobs after corn harvesting), lignin has long been considered a challenge in biofuel production. However, WSU’s new technique has the potential to unlock its energy-rich properties.

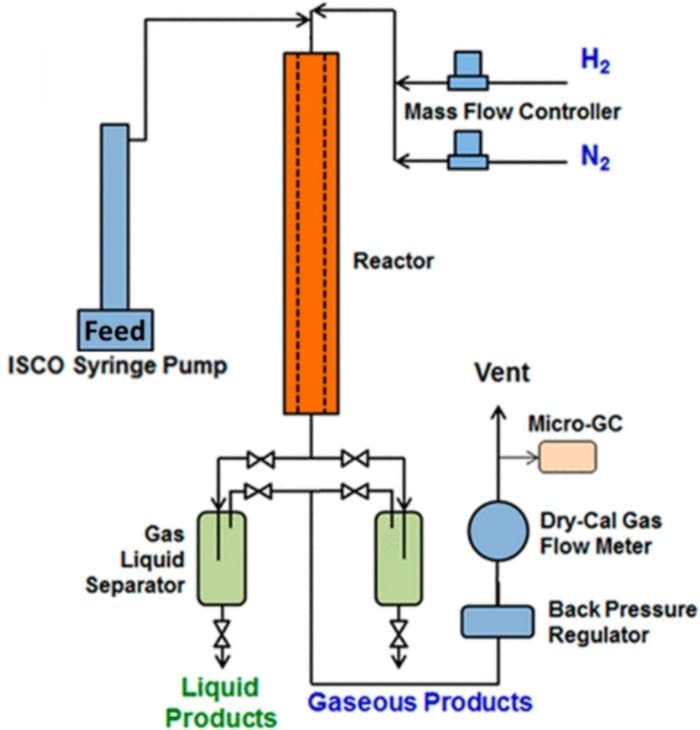

Using a continuous process known as “simultaneous depolymerization and hydrodeoxygenation,” the research team was able to break down lignin and remove oxygen atoms in one streamlined reaction, resulting in a lignin-based jet fuel. This approach represents a significant leap toward commercial viability, as it can produce fuel more efficiently and at a lower cost than previous methods.

The breakthrough is important as global aviation fuel consumption is expected to rise in the coming decades. In 2019, nearly 100 billion gallons of aviation fuel were used worldwide, with no signs of demand slowing. Transitioning to SAF made from plant biomass like lignin could play a key role in reducing aviation’s carbon emissions.

Lignin-based fuel offers a promising alternative to traditional fossil fuels. Unlike the aromatics currently used in aviation fuels, which contribute to contrail formation and climate impact, lignin-derived hydrocarbons are denser and more efficient. This allows them to replace fossil fuel aromatics while maintaining fuel performance in jet engines.

“The aviation enterprise is looking to generate 100% renewable aviation fuel,” said Josh Heyne, a member of the research team and co-director of the WSU-PNNL Bioproducts Institute. “Lignin-based jet fuel complements existing technologies by, for example, increasing the density of fuel blends.”

One key advantage of lignin-based fuel is its potential to be “drop-in” ready, meaning it can be used in existing aircraft engines and infrastructure without modification. This makes it an attractive option for airlines looking to reduce their carbon footprint without investing in costly new equipment.

WSU’s research differs from other studies in that it uses “technical lignin,” a less processed and cheaper form of lignin derived from corn stover. This makes the process not only more cost-effective but also more scalable for commercial production. Previous approaches have relied on bio-oil extracted from lignin, which is more expensive and less practical for large-scale fuel production.

While this is a major achievement, the team is continuing to refine the process to make it even more efficient and reduce costs further. “We’re working to create an effective, commercially relevant technology for a complementary blend component that can achieve the 100% drop-in goal,” added Heyne.

This latest breakthrough brings the aviation industry closer to a future where sustainable jet fuel is the norm, not the exception. If adopted on a global scale, lignin-based fuels could help the sector meet international carbon neutrality targets and reduce the environmental impact of flying.

Journal Reference:

Adarsh Kumar, David C. Bell, Zhibin Yang, Joshua Heyne, Daniel M. Santosa, Huamin Wang, Peng Zuo, Chongmin Wang, Ashutosh Mittal, Darryl P. Klein, Michael J. Manto, Xiaowen Chen, Bin Yang, ‘A simultaneous depolymerization and hydrodeoxygenation process to produce lignin-based jet fuel in continuous flow reactor’, Fuel Processing Technology 263, 108129 (2024). DOI: 10.1016/j.fuproc.2024.108129

Article Source:

Press Release/Material by Washington State University

Featured image credit: Rene Rauschenberger | Pixabay